Functionality of the Sprag Clutch Design

Sep 22, 2017|

Sep 22, 2017| View:1102

View:1102Functionality of the Sprag Clutch Design

How Do Sprag Clutches Work?

A sprag clutch resembles a roller bearing, but instead of allowing the elements to roll freely in both directions the rolling elements lock when rolled the opposite direction. Sprag clutches have three main operations: overrunning, indexing and backstopping. The sprag clutch consists of a series of cam shaped steel wedges (or sprags). Each sprag is placed at an angle to permit rotation in one direction, yet provides instantaneous backstopping in the other.

Torque is transmitted from one race to the other by the wedging action of the sprags, consistently providing safe and reliable performance. A sprag clutch is designed so that the maximum number of sprags can be accommodated, enabling greater torque transition in comparison to its size and weight.

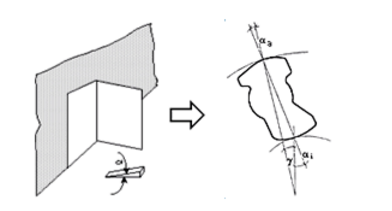

Function: The sprag clutch design shows at the contact surfaces a sophisticated geometrical shape, the engagement curve, which results in a certain pitch anglewhen the sprags get in contact with the round mating parts. When torque is applied to the clutch the sprags roll in along the engagement curve until an equilibrium of forces between the torque and tension in the sprags and mating parts is achieved. This part of the engagement curve is called operating zone.

The engagement curve has to meet the operating condition. The size of the engagement angle is determined by the applied torque and the force of reaction of the expansion of the mating parts. The engagement angle creates an angle of twist between outer an inner ring which will remain equal with constant operating conditions and should not be considered slippage or intermittent slippage.

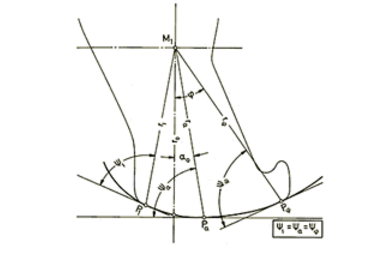

The logarithmic spiraled engagement curve

The logarithmic spiraled engagement curve is the prerequisite for precise indexing and long operating life. To achieve these factors it is important that all sprags engage simultaneously and with the same angle for torque pickup. Equal force acting on all sprags is required from the instant of engagement to full torque transfer.

The special geometric shape of the logarithmic spiral along the engagement curve guarantees equal pitch angles between the sprags and round mating parts in each position of the engagement curve. This angle remains equal even with different position angles of the sprags.

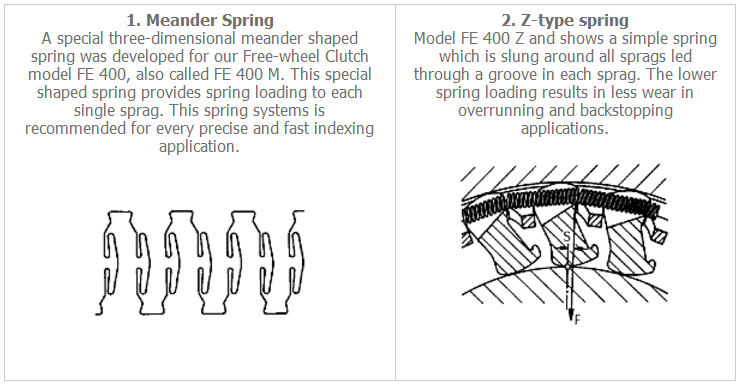

Spring System

In order to provide instant torque transmission, the sprags have to be kept in friction contact all the time reliably with a spring system. We provide two spring systems:

Identification The Standard design of model FE 400 includes the meander spring system even when the suffix "M" has not to be added. For Z-type spring please add suffix "Z", e.g. FE 442 Z, FR 422 Z etc. Please note that our ball bearing sized clutches are available with Z-type spring system only.

View More(Total0)Comment lists