Principles of Selecting Clutch Bearings

Dec 25, 2015|

Dec 25, 2015| View:651

View:651Principles of Selecting Clutch Bearings

Introductions of choosing the type of bearings and prerequisites for selection

How to choose a better overrunning clutch? Factors as follows we should take into consideration:

(1)Motor specification

(2)Starting torque of electric motor/rated torque

(3)rated driving torque

(4) range of rotating speed

(5) inertia of driven parts

(6)range of overrunning speed

(6)times of service life

(7)shaft diameter

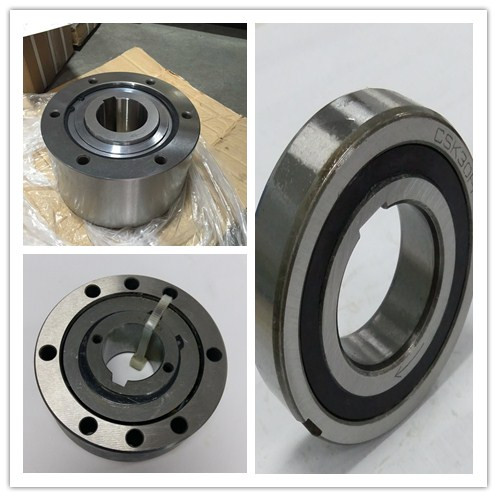

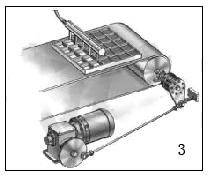

As shown in pic_1, we can use an overrunning clutch to depart the part with big inertia from the equipment while the equipment is braking. In this way, the overrunning clutch prevents the equipment from damage of inverse rotation.

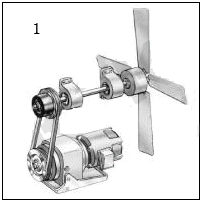

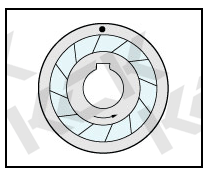

Picture 2, is shown the behavior of an over run clutch works in dual drive. When a failure happens in one side, the overrunning clutch will mesh with another drive system and ensure the whole system keep running.

We should think of some factors when we choose an indexing clutch:

(1) Max indexing times per minute

(2) The angle of indexing movement

(3) Rated torque

(4)inertia of driven parts

(5)The acceleration of transmission parts

(5)times of service life

(6)shaft diameter

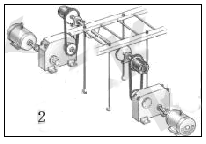

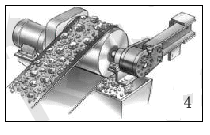

In the case as the picture (pic_3) shows, the motor is connected with the rod by an indexing clutch. With the indexing clutch, the roller will achieve intermittent movement, after that, materials can accurately drop to the container by a fixed step, and that step can be readjusted by gear rack. One way clutch bearings with indexing function are widely used in the package machines, food machines and printing machines.

The factors of choosing a better backstopping clutch that we will think of:

(1) Drag torque

(2)The max drag torque results from the elasticity between two endpoints on which the parts are fixed.

(3)range of overrunning speed

(4)times of service life

(5)shaft diameter

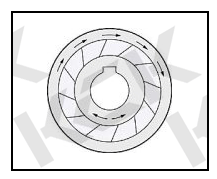

As is shown in the picture 4, the inner race of overrunning clutch can be fixed on the end of the belt pulley, or other shaft rotating in low speed, and the outer race will be fixed in the rack of the conveyor to avoid reversion. Except conveyor, this system can be also used to keep inclined pump and screw pump from reversion.

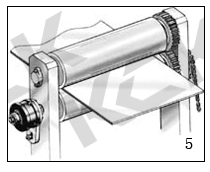

Picture 5 is shown that backstopping clutches are applied to rolling mill. In order to let steel plates move in the same direction, the backstop clutch will play an important role in preventing the roller from inverse rotation.

View More(Total0)Comment lists