The BS series Cam Clutches are intended for applications where reverse rotation of the slow speed conveyor head shaft is to be prevented (backstopping).

0

0BS & BS-HS SERIES CAM CLUTCH

The BS series Cam Clutches are intended for

applications where reverse rotation of the slow speed

conveyor head shaft is to be prevented (backstopping).

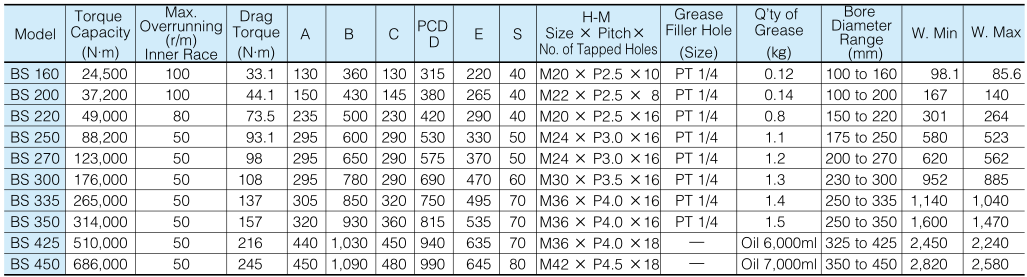

Dimensions and Capacities

W. Min Weight at Minimum Bore

W. Max Weight at Maximum Bore

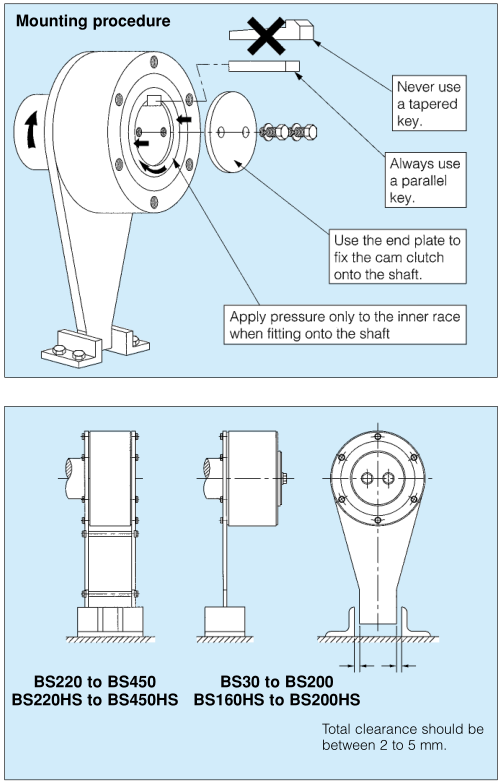

Installation and Usage | ■ INSTALLATION AND USAGE |

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102