0

0| Data Sheet | ||

| Item | BSEU40-25 | |

| Material | GCr15 | |

| Bore size | 25mm | |

| Outer dia. | 118mm | |

| Keyway | 6*2.8mm | |

| Torque capacity | 1440 Nm | |

| Inner race max. overrunning speed | 450r/min | |

| Weight | 3.363-3.781 kg | |

| Package | wooden package or as your need | |

Product display

Feature

BSEU Series Cam Clutch Backstop Clutch was developed as European style Backstopping Cam Clutch which has easy usage. It has Cam & Roller construction that the roller works as a bearing same as the small size BS series backstop cam clutch. The outer race has special shape which was combined the torque arm, so only stopping the rotation is required. You can select the correct model from various bore size from 20 mm to 90 mm in each 5 mm. Backstopping for the country elevator or the foods conveying conveyor which is used in the factory is the recommendation. The recommends BS series Cam Clutch Backstop Clutch in the very dusty environment condition or the inclined conveyor and the bucket elevator which are used in outside location.

The Parameters of the BSEU series

| Model | Bore Size | Torque | Max.Overrunning |

|

|

|

|

|

|

|

|

|

|

|

| ||

Dia | Keyway | ||||||||||||||||

BSEU25 | 20 | 6×2.8 | 216 | 500 | 83 | 42 | 35 | 12 | 40 | 90 | 15 | 35 | 5 | 1 | 0.999 | 0.948 | |

BSEU25 | 25 | 8×3.3 | 216 | 500 | 83 | 42 | 35 | 12 | 40 | 90 | 15 | 35 | 5 | 1 | |||

BSEU40 | 20 | 6×2.8 | 1,440 | 450 | 118 | 60 | 55 | 15 | 40 | 110 | 15 | 35 | 8 | 1.5 | 3.781 | 3.363 | |

BSEU40 | 25 | 8×3.3 | 1,440 | 450 | 118 | 60 | 55 | 15 | 40 | 110 | 15 | 35 | 8 | 1.5 | |||

BSEU40 | 30 | 8×3.3 | 1,440 | 450 | 118 | 60 | 55 | 15 | 40 | 110 | 15 | 35 | 8 | 1.5 | |||

BSEU40 | 35 | 10×3.3 | 1,440 | 450 | 118 | 60 | 55 | 15 | 40 | 110 | 15 | 35 | 8 | 1.5 | |||

BSEU40 | 40 | 12×3.3 | 1,440 | 450 | 118 | 60 | 55 | 15 | 40 | 110 | 15 | 35 | 8 | 1.5 | |||

BSEU70 | 45 | 14×3.8 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 1.5 | 7.607 | 6.541 | |

BSEU70 | 50 | 14×3.8 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 1.5 | |||

BSEU70 | 55 | 16×4.3 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 2 | |||

BSEU70 | 60 | 18×4.4 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 2 | |||

BSEU70 | 65 | 18×4.4 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 2 | |||

BSEU70 | 70 | 20×4.9 | 3,140 | 350 | 165 | 90 | 59 | 20 | 80 | 140 | 18 | 35 | 10 | 2 | |||

BSEU90 | 75 | 20×4.9 | 4,700 | 250 | 190 | 120 | 63 | 20 | 80 | 165 | 20 | 40 | 15 | 2 | 10.046 | 9.265 | |

BSEU90 | 80 | 22×5.4 | 4,700 | 250 | 190 | 120 | 63 | 20 | 80 | 165 | 20 | 40 | 15 | 2 | |||

BSEU90 | 85 | 22×5.4 | 4,700 | 250 | 190 | 120 | 63 | 20 | 80 | 165 | 20 | 40 | 15 | 2 | |||

BSEU90 | 90 | 25×5.4 | 4,700 | 250 | 190 | 120 | 63 | 20 | 80 | 165 | 20 | 40 | 15 | 2 | |||

W. Min Weight at Minimum Bore;W. Max Weight at Maximum Bore

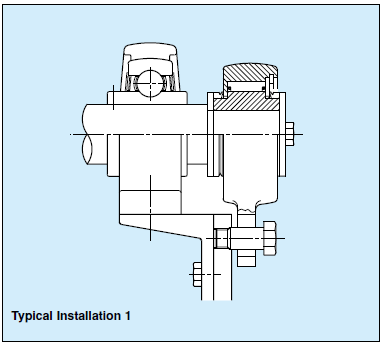

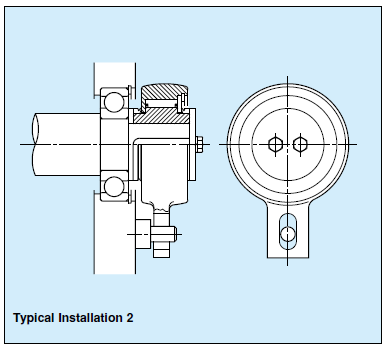

Installation and usage for BSEU series

1. Suma bearing factory recommend using a shaft tolerance of h7 or h8 for backstop cam clutch installation.

2. ISO R773 (DIN6885.1) keyway is standard.

3. Before installation, verify that the direction of rotation of the inner race of the backstop cam clutch (shown by the arrow on the inner race) is the same as the direction of rotation of the conveyor.

4. When inserting the Cam Clutch on the shaft, apply pressure only on the surface of the inner race with a soft hammer. Never strike the Cam Clutch with a steel hammer or apply unnecessary impact loads.

5. Always use a parallel key for installation onto the shaft and then fix the Cam Clutch Backstop Clutch to the shaft with the end plate. Never use a tapered key. Allow for a clearance between the top of the clutch keyway and the top of the key for pressure ventilation. A pressure ventilation hole is provided on the keyway of the clutch’s inner race.

6. Use the frame or a pin to eliminate outer race rotation.

7. Set a 0.5 mm degree clearance between the torque arm and the frame (torque arm stopper) or the long slit in the torque arm and the pin. If the torque arm is rigidly mounted, it will apply a load to the Cam Clutch which may eventually damage it.

8. The backstop cam clutch is pre-packed with low temperature grease before shipment and is ready for installation and operation. No lubrication maintenance is required. The ambient operational temperature range is –40° to 50°C. However, the maximum temperature should be determined depending on the number of shaft revolutions. Further, if the number of shaft revolutions is low, a higher ambient operational temperature range is allowable.

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102