mi cam clutch

mz cam clutch

MX SERIES CAM CLUTCH

For General Applications

0

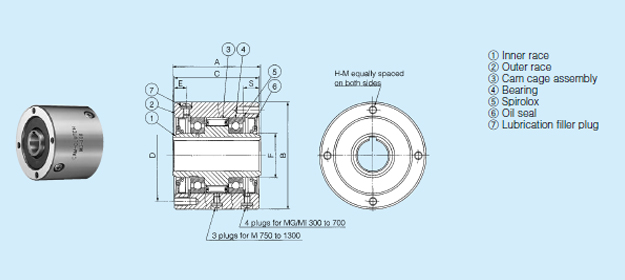

0MODELS MG300 TO MG1300/MI300 TO MI1300

For General Applications

| Model | Torque Capacity (Nm) | Drag Torqwe (Nm) | Max Overrunning (r/min) | Max Indexing (cycle/min) | Bore Size | A | B (H7) | C | PCD D | E | F | S | H-M No. of Tapped Holes × Size × Pitch | Lubric cation FllerPlug Size x Pitch | Oil (ml) | Weight (kg) | ||

| Inner Race | Outer Race | Dia (H7) | Keywey | |||||||||||||||

MG 300 ML 300 | 314 | 0.23 0.31 | 2800 50 | 900 -- | -- 300 | 19 | 5*2 | 63 | 77 | 60 | 66 | 10.4 | 28.5 | 13 | 4 × M 6 × P1.0 | M6 × P1.0 | 25 50 | 1.8 |

MG 400 ML 400 | 539 | 0.29 0.38 | 2600 50 | 800 -- | -- 300 | 22 | 5*2 | 70 | 88 | 67 | 73 | 10.7 | 31.7 | 16 | 4 × M 8 × P1.25 | M6 × P1.0 | 30 60 | 2.7 |

MG 500 ML 500 | 1620 | 0.51 0.68 | 2400 50 | 800 -- | -- 300 | 31.5 | 7*3 | 89 | 108 | 86 | 92 | 12.3 | 44.4 | 16 | 4 × M 8 × P1.25 | M6 × P1.0 | 50 100 | 5.0 |

MG 600 ML 600 | 3140 | 0.85 1.54 | 2100 50 | 700 -- | -- 300 | 50 | 12*3.5 | 95 | 136 | 92 | 120 | 12.8 | 69.8 | 16 | 6 × M 8 × P1.25 | M6 × P1.0 | 80 160 | 8.6 |

MG 700 ML 700 | 5880 | 1.70 2.63 | 1500 30 | 500 -- | -- 300 | 70 | 18*6 | 127 | 180 | 124 | 160 | 19.8 | 101.5 | 20 | 6 × M 10 × P1.5 | M6 × P1.0 | 135 260 | 19.5 |

MG 750 ML 750 | 9500 | 3.43 4.12 | 1800 30 | 600 -- | -- 300 | 85 | 24*6 | 153 | 200 | 150 | 175 | 75 | 110 | 25 | 8 × M 14 × P2.0 | M8 × P1.25 | 400 800 | 37.0 |

MG 800 ML 800 | 17600 | 5.39 8.33 | 1300 30 | 475 -- | -- 300 | 110 | 28*7 | 158 | 250 | 155 | 220 | 77.5 | 140 | 25 | 8 × M 16 × P2.0 | M8 × P1.25 | 500 1000 | 46.5 |

MG 900 ML 900 | 24500 | 6.77 9.41 | 1200 20 | 400 -- | -- 300 | 135 | 35*9 | 165 | 300 | 160 | 265 | 80 | 170 | 32 | 10 × M 16 × P2.0 | M8 × P1.25 | 620 1240 | 70.5 |

MG 1000 ML 1000 | 33800 | 8.14 12.74 | 1200 20 | 325 -- | -- 300 | 160 | 38*10 | 188 | 370 | 180 | 325 | 90 | 200 | 32 | 12 × M 16 × P2.0 | M8 × P1.25 | 850 1700 | 108.5 |

MG 1100 ML 1100 | 78400 | 15.00 22.15 | 350 20 | -- | -- 150 | 185 | 45*14 | 260 | 470 | 250 | 415 | 125 | 260 | 40 | 12 × M 20 × P2.5 | M12 × P1.75 | 2900 5800 | 250 |

MG 1200 ML 1200 | 95100 | 17.64 27.54 | 300 20 | -- | -- 150 | 200 | 45*14 | 260 | 500 | 250 | 440 | 125 | 280 | 45 | 12 × M 24 × P3.0 | M12 × P1.75 | 3000 6000 | 280 |

MG 1300 ML 1300 | 176000 | 18.72 28.13 | 250 20 | -- | -- 150 | 250 | 56*17.5 | 280 | 600 | 260 | 530 | 130 | 340 | 50 | 12 × M 30 × P3.5 | M12 × P1.75 | 3800 7600 | 410 |

Installation and Usage

1. MG Series Cam Clutch from Suma bearing vendor is used for inner race overrunning applications. MI Series Cam Clutch from Suma bearing vendor is used for indexing applications.

2. For attaching a pulley, a gear, or sprocket to the clutch, insert the clutch into the hub of the device,

and screw the bolts (high tension) into the tapped holes on the clutch end. The tolerance bore of the hub

should be H6 or H7 of JIS standard.

3. Recommended shaft tolerances are as follows:

| Model | Tolerance |

| M300, M400 | +0 to -0.021 |

| M500, M600 | +0 to -0.025 |

| M700 | +0 to -0.030 |

| M750, M800 | +0 to -0.035 |

| M900, M1000 | +0 to -0.040 |

| M100, M1200, M1300 | +0 to -0.046 |

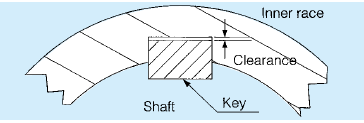

4. The key should be in accordance with JIS B1301-1959. However, for M750 and above models, a key is attached.

5. Use only a parallel key to secure the clutch. Never use a tapered key.

6. If the clutch receives shock loads or is designed for use at full torque capacity, it is better to use a

hardened key and shaft.

7. Allow for a clearance between the top of the clutch keyway and the top of the key for pressure

ventilation of the clutch in the case of MG Series. A pressure ventilation hole is provided on the keyway of the clutch inner race.

8. When mounting the clutch on a shaft, apply pressure to the inner race, but never to the outer race.

9. Thrust load should be taken up by other devices, not by the Cam Clutch.

10. When using MG Series at medium and high speeds, pay attention to heating. Longevity is shortened if the temperature of Cam Clutch outer race rises to over 70°C. In case of continuous over running

In this case, use a different model or provide an oil bath or forced lubrication.

11. Oil is not sealed in at the time of shipment. Supply an appropriate amount of oil before use.

Product Display

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102