0

0Features

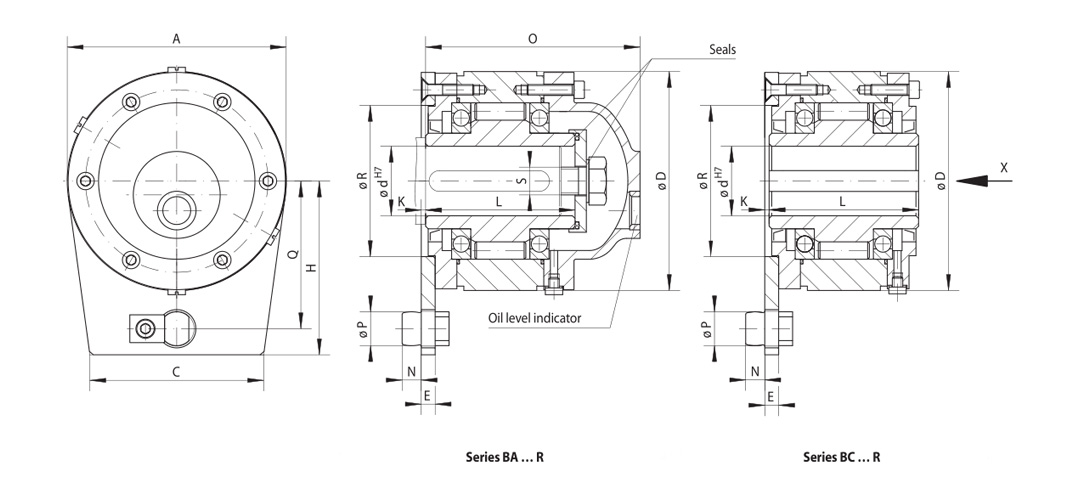

Complete Freewheels BA … R and BC … R with lever arm are sealed roller freewheels with ball bearings.

The freewheels BA … R have an end cover and are fitted to shaft ends. The oil filling is carried out after the freewheel has been installed to the end of the shaft.

The freewheels BC … R are supplied oil-filled and are arranged on through shafts or shaft ends.

The freewheels BA … R and BC … R are used as:

➧Backstops

for applications with low to medium speed freewheeling operation.

Nominal torques up to 57 500 Nm.

Bores up to 150 mm.

Application example

Complete Freewheel BA 90 R as a backstop on the end of a transport roller. The backdriving torque is supported by the lever arm with holding pin on the base. If the holding pin is removed, the shaft can be turned in both directions.

Freewheel Size | Type | Nominal | Max. speed | Bore d | A | C | D | E | H | K | L | N | O | P | Q | R | S | Weight | ||||

BA | 12 | BC | 12 | R | 150 | 1 750 | 15 | 15 | 71 | 50 | 71 | 8 | 53 | 4,5 | 68 | 9 | 91 | 11,5 | 42 | 45 | M 6 | 2 |

BA | 15 | BC | 15 | R | 230 | 1 650 | 20 | 20 | 81 | 60 | 81 | 8 | 62 | 4,5 | 70 | 9 | 93 | 13,5 | 50 | 50 | M 6 | 3 |

BA | 18 | BC | 18 | R | 340 | 1 550 | 25 | 25 | 96 | 70 | 96 | 8 | 73 | 4,5 | 70 | 9 | 96 | 15,5 | 60 | 60 | M 10 | 4 |

BA | 20 | BC | 20 | R | 420 | 1 450 | 30 | 30 | 110 | 90 | 106 | 8 | 80 | 2,5 | 77 | 11 | 104 | 19,5 | 65 | 70 | M 10 | 5 |

BA | 25 | BC | 25 | R | 800 | 1 250 | 40 | 40 | 126 | 100 | 126 | 8 | 90 | 2,5 | 93 | 11 | 125 | 19,5 | 75 | 80 | M 12 | 8 |

BA | 28 | BC | 28 | R | 1 200 | 1 100 | 45 | 45 | 140 | 110 | 136 | 10 | 105 | 3,5 | 95 | 14 | 129 | 24,5 | 85 | 90 | M 12 | 9 |

BA | 30 | BC | 30 | R | 1 600 | 1 000 | 50 | 50 | 155 | 120 | 151 | 10 | 120 | 3,5 | 102 | 16 | 140 | 27,5 | 95 | 100 | M 16 | 12 |

BA | 35 | BC | 35 | R | 1 800 | 900 | 55 | 55 | 170 | 130 | 161 | 10 | 140 | 3,5 | 110 | 19 | 151 | 33,5 | 112 | 110 | M 16 | 15 |

BA | 40 | BC | 40 | R | 3 500 | 800 | 60 | 60 | 190 | 150 | 181 | 12 | 160 | 5,5 | 116 | 22 | 160 | 37,5 | 130 | 120 | M 16 | 20 |

BA | 45 | BC | 45 | R | 7 100 | 750 | 70 | 70 | 210 | 160 | 196 | 14 | 175 | 7,0 | 130 | 26 | 176 | 41,5 | 140 | 130 | M 16 | 25 |

BA | 50 | BC | 50 | R | 7 500 | 700 | 75 | 75 | 220 | 180 | 206 | 14 | 185 | 7,0 | 132 | 26 | 178 | 41,5 | 150 | 140 | M 16 | 30 |

BA | 52 | BC | 52 | R | 9 300 | 650 | 80 | 80 | 230 | 190 | 216 | 14 | 200 | 4,5 | 150 | 26 | 208 | 41,5 | 160 | 150 | M 20 | 35 |

BA | 55 | BC | 55 | R | 12 500 | 550 | 90 | 90 | 255 | 200 | 246 | 15 | 210 | 3,5 | 170 | 29 | 228 | 49,5 | 170 | 160 | M 20 | 50 |

BA | 60 | BC | 60 | R | 14 500 | 500 | 105 | 295 | 220 | 291 | 20 | 250 | 8,5 | 206 | 35 | 273 | 60,0 | 200 | 190 | M 24 | 91 | |

BA | 70 | BC | 70 | R | 22 500 | 425 | 120 | 335 | 260 | 321 | 25 | 280 | 14,0 | 215 | 39 | 291 | 65,0 | 225 | 210 | M 24 | 115 | |

BA | 80 | BC | 80 | R | 25 000 | 375 | 130 | 360 | 280 | 351 | 30 | 280 | 18,5 | 224 | 39 | 302 | 65,0 | 225 | 220 | M 24 | 150 | |

BA | 90 | BC | 90 | R | 33 500 | 350 | 140 | 385 | 300 | 371 | 35 | 310 | 22,5 | 236 | 55 | 314 | 70,0 | 250 | 240 | M 30 | 180 | |

BA | 95 | BC | 95 | R | 35 000 | 300 | 150 | 400 | 350 | 391 | 40 | 310 | 27,5 | 249 | 55 | 337 | 70,0 | 250 | 250 | M 30 | 225 | |

BA 100 | BC 100 | R | 57 500 | 250 | 150 | 420 | 380 | 411 | 45 | 345 | 31,5 | 276 | 60 | 372 | 80,0 | 280 | 270 | M 30 | 260 | |||

The maximum transmissible torque is 2 times the specified nominal torque. See page 14 for determination of selection torque.

Keyway according to DIN 6885, page 1 • Tolerance of keyway width JS10.

Mounting The backdriving torque is supported by the lever arm with holding pin. The holding pin e ngages in a slot or bore in the frame of the machine. It must have 0,5 to 2 mm play in the axial and radial directions. If the holding pin is removed, the shaft can be turned in both directions. The tolerance of the shaft must be ISO h6 or j6. | The freewheels BC … R are supplied oil-filled and ready for installation. | Example for ordering |

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102