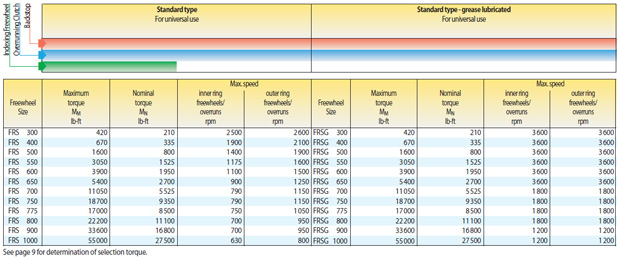

The freewheels FRS are supplied oil-filled.

The freewheels FRSG are supplied grease filled.

0

0Complete Freewheels FRS and FRSG

Features

Complete Freewheels FRS and FRSG are sealed sprag freewheels with ball bearings and ready for installation.

The freewheels FRS are supplied oil-filled.

The freewheels FRSG are supplied grease filled.

The freewheels FRS and FRSG are used as:

➧ Backstops

➧ Overrunning Clutches

➧ Indexing Freewheels

Maximum torques up to 55 000 lb-ft.

Bores up to 7 inch. Standard bores in inch dimension are available from stock. Metric bores on request.

Application example

Complete Freewheels FRS 600 in both drive units of a transport system with a conveyor belt that moves both forward and backward (reversible operation). In order to ensure that the conveyor belt is moved under tension, forward movement is driven by drive unit I, reverse movement by drive unit II. The freewheels automatically disengage the respective non working drive, eliminating the need for expensive external clutches or brakes.

For forward movement, drive unit II is started in freewheeling direction of freewheel II; free - wheel II is in freewheeling operation and disengages drive unit II from the conveyor belt. Afterwords drive unit I is started in the locking direction of the freewheel I; freewheel I is in driving operation and the conveyor belt is moved forward by drive unit I. The speed of drive unit I is lower than that of drive unit II. Thus freewheel II remains in freewheeling operation and drive unit II is not improperly engaged.

For reverse movement, the drive units are started in reverse order and direction of rotation at the corresponding speeds.

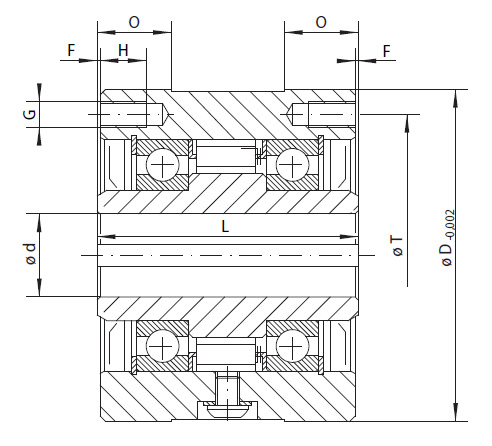

| Freewheel Size | Bo Standard bore inch | re d s | max. inch | D inch | F inch | G Thread | L inch | H inch | O inch | T inch | Z* | Weight lbs | |||||||

| FR 300 | 0.500 | 0.650 | 0.750 | 0.750 | 3.000 | 0.063 | 0.250-28 | 2.500 | 0.375 | 0.750 | 2.625 | 4 | 3.5 | ||||||

| FR 400 | 0.500 | 0.625 | 0.750 | 0.875 | 1.000 | 1.125 | 1.125 | 3.500 | 0.032 | 0.312-24 | 2.750 | 0.500 | 0.750 | 2.875 | 4 | 6.0 | |||

| FR 500 | 0.875 | 1.000 | 1.125 | 1.250 | 1.312 | 1.312 | 4.250 | 0.063 | 0.312-24 | 3.500 | 0.625 | 1.000 | 3.625 | 4 | 10.0 | ||||

| FR 550 | 1.250 | 1.312 | 1.500 | 1.625 | 1.625 | 4.750 | 0.063 | 0.312-24 | 3.250 | 0.540 | 0.750 | 4.250 | 6 | 12.0 | |||||

| FR 650 | 1.938 | 2.000 | 2.250 | 2.438 | 2.500 | 2.500 | 6.500 | 0.063 | 0.375-24 | 3.500 | 0.750 | 1.000 | 5.750 | 8 | 24.0 | ||||

| FR 700 | 1.938 | 2.000 | 2.250 | 2.438 | 2.500 | 2.750 | 2.938 | 2.938 | 7.125 | 0.063 | 0.375-24 | 5.000 | 0.750 | 1.000 | 6.250 | 8** | 42.0 | ||

| FR 750 | 2.438 | 2.500 | 2.938 | 3.000 | 3.250 | 3.438 | 3.438 | 8.750 | 0.063 | 0.500-20 | 6.000 | 0.875 | 1.250 | 7.000 | 8** | 83.0 | |||

| FR 775 | 2.750 | 2.938 | 3.000 | 3.250 | 3.438 | 3.500 | 3.750 | 3.750 | 9.750 | 0.063 | 0.500-20 | 6.000 | 0.875 | 1.250 | 8.500 | 8 | 96.0 | ||

| FR 800 | 3.000 | 3.250 | 3.438 | 3.500 | 3.750 | 3.937 | 4.000 | 4.250 | 4.500 | 4.500 | 10.000 | 0.063 | 0.500-20 | 6.000 | 0.875 | 1.250 | 8.937 | 8 | 102.0 |

| FR 900 | 4.000 | 4.438 | 4.500 | 4.938 | 5.000 | 5.438 | 5.438 | 12.000 | 0.063 | 0.625-18 | 6.375 | 1.000 | 1.375 | 9.750 | 10 | 156.0 | |||

| FR 1000 | 5.750 | 5.938 | 6.000 | 6.750 | 6.875 | 7.000 | 7.000 | 15.000 | 0.063 | 0.625-18 | 6.625 | 1.000 | 1.375 | 11.750 | 12 | 250.0 | |||

* Z = Number of tapped holes G on pitch circle T.

** Six holes are equally spaced 60° apart with two additional holes located 30° from the six equally spaced holes and 180° apart.

Keyway dimensions upon request by customers.

| Mounting The customer attachment part is centered on the external diameter D and then bolted on to the face. The recommended tolerance of the shaft is + 0 / - 0.001 inch and the tolerance of the pilot diameter D of the attachment part is - 0 / + 0.002 inch. | Labyrinth Seals Labyrinth seals are available to provide addi - tional protection for harsh environments. |

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102