lubricated.

0

0Features

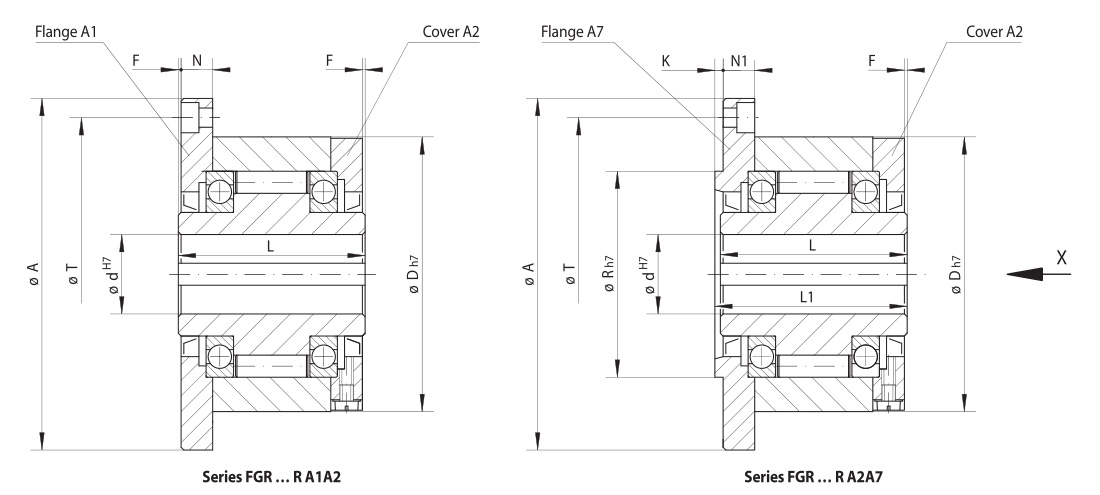

Complete Freewheels FGR … R A1A2 and

FGR … R A2A7 with mounting flange are sealed

roller freewheels with ball bearings. They are oil

lubricated.

The freewheels FGR … R A1A2 and FGR … R

A2A7 are used as:

➧ Backstops

➧ Overrunning Clutches

➧ Indexing Freewheels

Nominal torques up to 68 000 Nm.

Bores up to 150 mm.

Application example

Complete Freewheel FGR 50 R A1A2, used in a

hydraulically released, spring actuated multi-

disk brake for winch drives. When the load is lif-

ted, the multiple-disk brake is closed and the

inner ring is freewheeling. At a standstill, the

freewheel functions as a backstop. The load is

held by the brake and the locked freewheel.

When lowering, the brake is released with

control and the load is lowered via the locked

freewheel. By using the freewheel, the hydraulic

control could be designed in an simpler and

more cost-effective manner.

Freewheel Size | Type | Flange and cover combination | Nominal t orque | M | ax. speed | Bore d | A | D | F | G** | K | L | L1 | N | N1 | R | T | Z** | Weight | ||

FGR | 12 | R | A1A2 | A2A7 | 55 | 2 500 | 5 400 | 12 | 85 | 62 | 1 | M 5 | 3,0 | 42 | 44 | 10,0 | 10,0 | 42 | 72 | 3 | 1,2 |

FGR | 15 | R | A1A2 | A2A7 | 130 | 2 200 | 4 800 | 15 | 92 | 68 | 1 | M 5 | 3,0 | 52 | 54 | 11,0 | 11,0 | 47 | 78 | 3 | 1,6 |

FGR | 20 | R | A1A2 | A2A7 | 180 | 1 900 | 4 100 | 20 | 98 | 75 | 1 | M 5 | 3,0 | 57 | 59 | 10,5 | 10,5 | 55 | 85 | 4 | 1,9 |

FGR | 25 | R | A1A2 | A2A7 | 290 | 1 550 | 3 350 | 25 | 118 | 90 | 1 | M 6 | 3,0 | 60 | 62 | 11,5 | 11,5 | 68 | 104 | 4 | 2,9 |

FGR | 30 | R | A1A2 | A2A7 | 500 | 1 400 | 3 050 | 30 | 128 | 100 | 1 | M 6 | 3,0 | 68 | 70 | 11,5 | 11,5 | 75 | 114 | 6 | 3,9 |

FGR | 35 | R | A1A2 | A2A7 | 730 | 1 300 | 2 850 | 35 | 140 | 110 | 1 | M 6 | 3,5 | 74 | 76 | 13,5 | 13,0 | 80 | 124 | 6 | 4,9 |

FGR | 40 | R | A1A2 | A2A7 | 1 000 | 1 150 | 2 500 | 40 | 160 | 125 | 1 | M 8 | 3,5 | 86 | 88 | 15,5 | 15,0 | 90 | 142 | 6 | 7,5 |

FGR | 45 | R | A1A2 | A2A7 | 1 150 | 1 100 | 2 400 | 45 | 165 | 130 | 1 | M 8 | 3,5 | 86 | 88 | 15,5 | 15,0 | 95 | 146 | 8 | 7,8 |

FGR | 50 | R | A1A2 | A2A7 | 2 100 | 950 | 2 050 | 50 | 185 | 150 | 1 | M 8 | 4,0 | 94 | 96 | 14,0 | 13,0 | 110 | 166 | 8 | 10,8 |

FGR | 55 | R | A1A2 | A2A7 | 2 600 | 900 | 1 900 | 55 | 204 | 160 | 1 | M 10 | 4,0 | 104 | 106 | 18,0 | 17,0 | 115 | 182 | 8 | 14,0 |

FGR | 60 | R | A1A2 | A2A7 | 3 500 | 800 | 1 800 | 60 | 214 | 170 | 1 | M 10 | 4,0 | 114 | 116 | 17,0 | 16,0 | 125 | 192 | 10 | 16,8 |

FGR | 70 | R | A1A2 | A2A7 | 6 000 | 700 | 1 600 | 70 | 234 | 190 | 1 | M 10 | 4,0 | 134 | 136 | 18,5 | 17,5 | 140 | 212 | 10 | 20,8 |

FGR | 80 | R | A1A2 | A2A7 | 6 800 | 600 | 1 400 | 80 | 254 | 210 | 1 | M 10 | 4,0 | 144 | 146 | 21,0 | 20,0 | 160 | 232 | 10 | 27,0 |

FGR | 90 | R | A1A2 | A2A7 | 11 000 | 500 | 1 300 | 90 | 278 | 230 | 1 | M 12 | 4,5 | 158 | 160 | 20,5 | 19,0 | 180 | 254 | 10 | 40,0 |

FGR 100 | R | A1A2 | A2A7 | 20 000 | 350 | 1 100 | 100 | 335 | 270 | 1 | M 16 | 5,0 | 182 | 184 | 30,0 | 28,0 | 210 | 305 | 10 | 67,0 | |

FGR 130 | R | A1A2 | A2A7 | 31 000 | 250 | 900 | 130 | 380 | 310 | 1 | M 16 | 5,0 | 212 | 214 | 29,0 | 27,0 | 240 | 345 | 12 | 94,0 | |

FGR 150 | R | A1A2 | A2A7 | 68 000 | 200 | 700 | 150 | 485 | 400 | 1 | M 20 | 5,0 | 246 | 248 | 32,0 | 30,0 | 310 | 445 | 12 | 187,0 | |

The maximum transmissible torque is 2 times the specified nominal torque. See page 14 for determination of selection torque.

Keyway according to DIN 6885, page 1 • Tolerance of keyway width JS10.

** Z = Number of fastening holes for screws G (DIN EN ISO 4762) on pitch circle T.

Mounting | Example for ordering Freewheel size FGR 25, standard type with flange A1 and cover A2: • FGR 25 R A1A2 Basic Freewheel, flange, cover, seals and screws are supplied loose provided nothing else is stated in the order. If assembled, oil-filled, Complete Freewheels are to be supplied, this must be specified in the order. When ordering, please also specify the free wheeling direction of the inner ring when view ed in direction X: • counterclockwisefree or • clockwise free |

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102