0

0Features

Internal Freewheels FXN are sprag freewheels without bearing support and with sprag lift-off X.

The sprag lift-off X ensures a wear-free free -wheeling operation when the inner ring rotates at high speed.

The outer ring is pressed into the customer hous ing. This makes compact, space-saving fit-ting solutions possible.

The freewheels FXN are used as:

➧ Backstops

➧ Overrunning Clutches

for applications with high speed freewheel ing operation and when used as an overrunning clutch with low speed driving operation.

Nominal torques up to 20 500Nm. The torque is transmitted on the outer ring by press fit.

Bores up to 130 mm. Many standard bores areavailable.

Sprag lift-off X

Internal Freewheels FXN are equipped with sprag lift-off X. The sprag lift-off X is used for backstops and overrunning clutches, provided that in freewheeling operation the inner ring is rotating at high speed and providing with overrunning clutches that the driving operation is conducted at low speed. In freewheeling operation, the centrifugal force F C causes the sprag to lift off from the outer track. In this operating state, the freewheel works wear-free,i.e. with unlimited service life.

Figure 76-2 shows a freewheel with sprag lift-off X in freewheeling operation. The sprags,which are supported in a cage connected with the inner ring, rotate with the inner ring. Thecentrifugal force F C that is applied in the center of gravity S of the sprag turns the sprag coun-terclockwiseand rests against the support ring of the cage. This results in the gap a between the sprag and the outer track; the freewheel works with out contact. If the inner ring speed decreases to such an extent that the effect of the centrifugal force on the sprag is less than that of the spring force FF , the sprag again rests on the outer ring and the freewheel is ready to lock (figure 76-3). If used as an overrunning clutch, the driving speed must not exceed 40% of the lift-off speed.

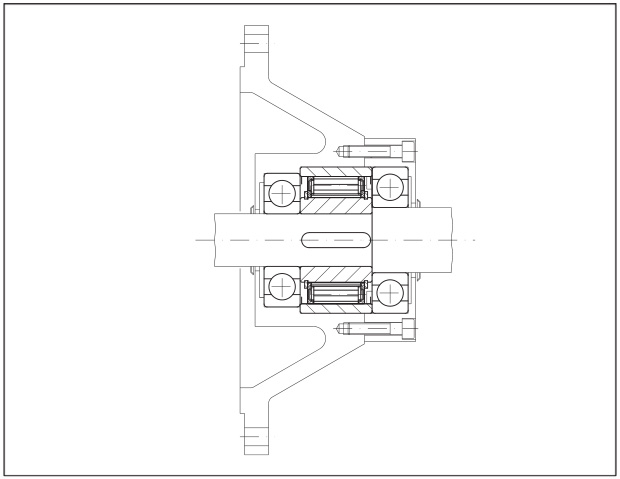

Application example

Internal Freewheel FXN 38 - 17/70 NX as a backstop, arranged in a housing adapter to attach to an electric motor. The thin outer ring that is pressed into the housing enables a space-efficient fitting solution. Due to the high shaft speeds in normal operation (freewheeling o peration), the sprag lift-off X ensures a contactless and hence wear-free continuous oper ation.

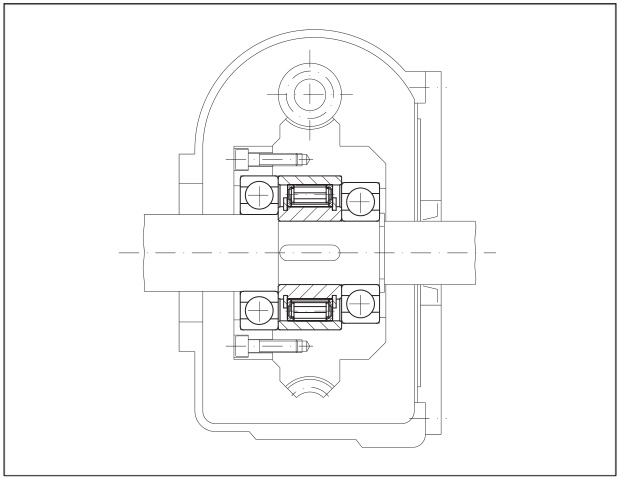

Application example

Internal Freewheel FXN 66 - 25/100 NX as an overrunning clutch in the creep drive of a textile machine. The freewheel installation is compactly solved by means of the thin outer ring that is pressed into the worm wheel. During setup, the machine is driven by the worm gear and the freewheel that is working in driving operation. In normal operation (freewheeling oper ation), the inner ring that is located on the high speed main drive shaft overruns and automatically disengages the creep drive. With the high overrunning speed of the inner ring, the type with sprag lift-off X is used; the sprags work in freewheeling operation without contact and hence are wear-free.

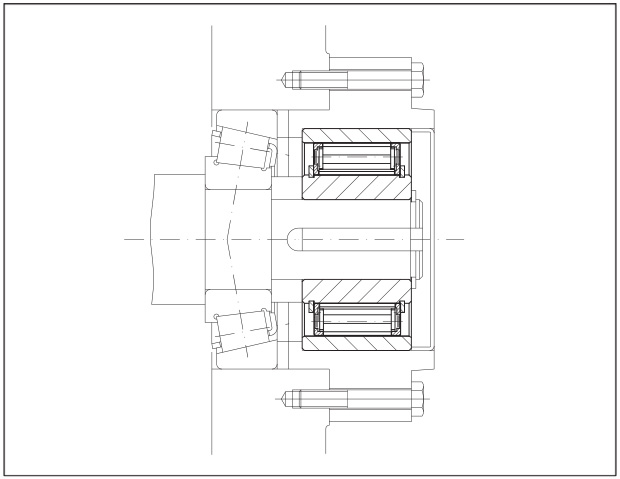

Application example

Internal Freewheel FXN 85 - 40/140 MX as a backstop fitted to the end of the first inter mediate shaft of a spur gearbox in the drive of an inclined conveyor belt. In the case of a motor stop the conveyor belt must be held securely so that the conveyor goods do not pull the belt backwards and possibly cause serious damage. Due to the high shaft speeds in normal oper ation (free wheeling operation), the sprag lift-off X ensures a contactless and hence wear-free c ontinuo us operation.

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102