0

0BREU SERIES CAM CLUTCH

Capacities

Model | Torque Capacity | Inner Race Overrunning Speed | Max.Engagement | |

N·m | Min. (r/min) | Max. (r/min) | Speed(r/min) | |

BREU 30 (K) | 607 | 880 | 3600 | 350 |

BREU 35 (K) | 686 | 780 | 3600 | 300 |

BREU 40 (K) | 980 | 720 | 3600 | 300 |

BREU 45 (K) | 1078 | 670 | 3600 | 280 |

BREU 50 (K) | 1715 | 610 | 3600 | 240 |

BREU 55 (K) | 1960 | 580 | 3600 | 220 |

BREU 60 (K) | 3479 | 490 | 3600 | 200 |

BREU 70 (K) | 4735 | 480 | 3600 | 200 |

BREU 80 (K) | 6517 | 450 | 3600 | 190 |

BREU 90 (K) | 8526 | 420 | 3000 | 180 |

BREU100 (K) | 14210 | 460 | 2500 | 180 |

BREU130 (K) | 20384 | 420 | 2200 | 180 |

BREU150 (K) | 33908 | 370 | 1300 | 180 |

General Information for Installation and Usage

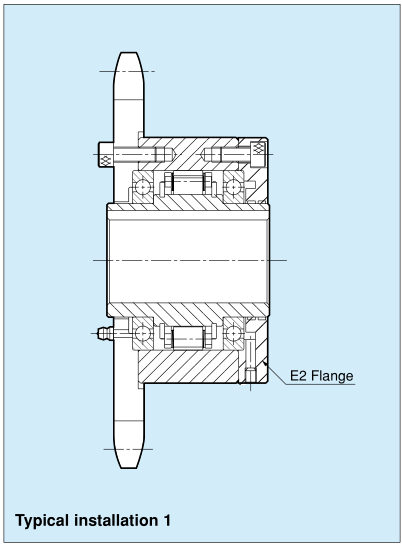

11. BREU series is a modular type Cam Clutch which is delivered as a BREU series Basic type or BREU-K series

with option parts (E1, E2, E5, E7 flanges, E3 Torque arm and E4 cover) which are required as separate parts.

12. All models are pre-greased.

The operational temperature range is –40°C to +40°C.

Too much additional grease to both bearing inhibits the basic Cam Clutch function. Refer to page 63 for the

maintenance.

13. We recommend a Shaft tolerance of h7, and DIN6885.1 keyway is standard.

14. We recommend tolerance of B and E H7 or H8 for sprockets, gears and other fitted parts.

15. Clean the surface of both end of the outer race and the contact surfaces of the flanges, torque arm and

cover.

16. Verify the direction of rotation and attach the flanges, torque arm or cover.

17. When installing sprocket, gear, and other equipment to the clutch, fit them on the surface of the flange by

using hexagon socket cap screws.

18. By installing each option part on the opposite side, the direction of rotation can be changed.

19. Fix the grease nipple and set screw to the option parts.

10. When mounting the clutch onto the shaft, apply pressure to the inner race but never to the outer race. Tap the

inner race lightly with a soft hammer moving around the race circumference so the Cam Clutch moves slowly

and uniformly onto the end of the shaft.

11. Do not use grease that contains EP additives.

12. Model No.

Capacities

BREU K

No Mark : No keyway on the outer race.

K : Keyway on the outer race.

Dimensions

Model | Bore Size | Keyway | A | B | C | D | E | F | G | H-J | K | L | b | t1 | Weight |

H7 | Inner Race | h7 | PCD | C | P10 | kg | |||||||||

BREU 30 (K) | 30 | 8x3.3 | 76 | 100 | 51 | 87 | 75 | 45 | 56 | 6-M6 | 10 | 1.0 | 8 | 4.0 | 2.7 |

BREU 35 (K) | 35 | 10x3.3 | 79 | 110 | 50 | 96 | 80 | 50 | 56 | 6-M6 | 12 | 1.0 | 10 | 5.0 | 3.2 |

BREU 40 (K) | 40 | 12x3.3 | 86 | 125 | 53 | 108 | 90 | 55 | 59 | 6-M8 | 14 | 1.3 | 12 | 5.0 | 4.4 |

BREU 45 (K) | 45 | 14x3.8 | 86 | 130 | 53 | 112 | 95 | 60 | 59 | 8-M8 | 14 | 1.3 | 14 | 5.5 | 4.7 |

BREU 50 (K) | 50 | 14x3.8 | 94 | 150 | 64 | 132 | 110 | 70 | 72 | 8-M8 | 14 | 1.3 | 14 | 5.5 | 7.6 |

BREU 55 (K) | 55 | 16x4.3 | 104 | 160 | 66 | 138 | 115 | 75 | 72 | 8-M10 | 16 | 1.5 | 16 | 6.0 | 8.9 |

BREU 60 (K) | 60 | 18x4.4 | 120 | 170 | 84 | 150 | 125 | 80 | 95 | 10-M10 | 16 | 1.5 | 18 | 7.0 | 12.5 |

BREU 70 (K) | 70 | 20x4.9 | 134 | 190 | 95 | 165 | 140 | 90 | 108 | 10-M10 | 16 | 1.8 | 20 | 7.5 | 17.2 |

BREU 80 (K) | 80 | 22x5.4 | 144 | 210 | 100 | 185 | 160 | 105 | 108 | 10-M10 | 16 | 1.8 | 22 | 9.0 | 22.4 |

BREU 90 (K) | 90 | 25x5.4 | 158 | 230 | 115 | 206 | 180 | 120 | 125 | 10-M12 | 20 | 2.0 | 25 | 9.0 | 30.3 |

BREU100(K) | 100 | 28x6.4 | 186 | 270 | 124 | 240 | 210 | 140 | 135 | 10-M16 | 24 | 2.0 | 28 | 10.0 | 45.5 |

BREU130(K) | 130 | 32x7.4 | 212 | 310 | 152 | 278 | 240 | 160 | 168 | 12-M16 | 24 | 2.5 | 32 | 11.0 | 67.0 |

BREU150(K) | 150 | 36x8.4 | 246 | 400 | 180 | 360 | 310 | 200 | 194 | 12-M20 | 32 | 2.5 | 36 | 12.0 | 145.0 |

Installation and Usage |  |

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102