0

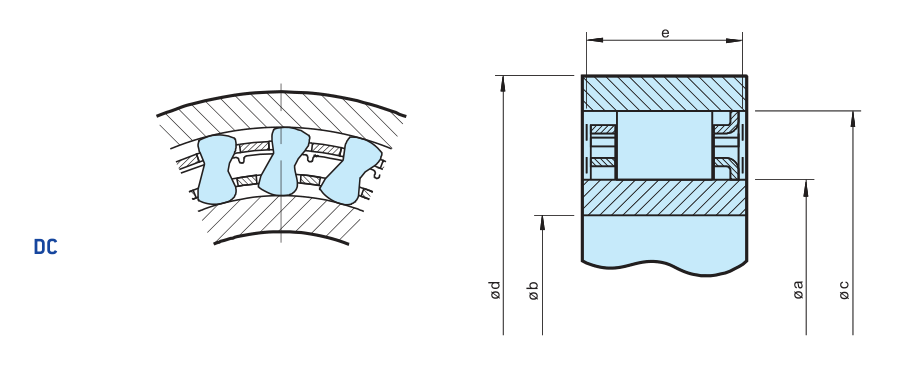

0Type DC is a sprag type freewheel cage from Suma industrial bearing supplier without inner or outer races. It must be installed in a design providing races, bearing support for axial and radial loads,lubrication and sealing. The DC type version-N accepts all types of lubricants currently used in the power transmis-sion equipement.

The sprag space tolerance must not be exceeded.Inner and outer races must both have a minimum plain width “e”, without any recess, to ensure the freewheel functions correctly as shown on following pages.

Alternatively, races can be made in case hardened steel shafts, or housings, to the specification below. Surface hardness of the finished part should be HRC 60 to 62, for a depth of 0,6 mm minimum.

Core hardness to be HRC35 to 45. Surface roughness not to exceed 22CLA. Maximum taper between races: 0,007 mm for 25 mm width.

Size |

| Overrunning speeds |

| Sprag space |

| Number clips of | Number sprags of | Weight | ||||

TKN1) | nimax2) | namax3) | Øa+0.008 | Øc± 0.013 | emin | Ødmin | Øbmax | |||||

[Nm] | [min -1] | [min -1] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg] | |||

DC2222G-N | 63 | 8600 | 4300 | 22.225 | 38.885 | 8.33±0.075 | 10 | 50 | 15 | – | 12 | 0.03 |

DC2776-N | 119 | 6900 | 3400 | 27.762 | 44.422 | 8.33±0.075 | 13.5 | 58 | 18 | – | 14 | 0.055 |

DC3034-N | 124 | 6300 | 3100 | 30.34 | 47 | 8.33±0.075 | 13.5 | 62 | 20 | – | 14 | 0.06 |

DC3175(3C)-N | 159 | 6000 | 3000 | 31.75 | 48.41 | 8.33±0.075 | 13.5 | 63 | 21 | 3 | 16 | 0.06 |

DC3809A-N | 275 | 5000 | 2500 | 38.092 | 54.752 | 8.33±0.075 | 16 | 71 | 25 | – | 18 | 0.085 |

DC4127(3C)-N | 224 | 4600 | 2300 | 41.275 | 57.935 | 8.33±0.075 | 13.5 | 75 | 27 | 3 | 18 | 0.09 |

DC4445A-N | 363 | 4300 | 2100 | 44.45 | 61.11 | 8.33±0.1 | 16 | 79 | 29 | – | 20 | 0.095 |

DC4972(4C)-N | 306 | 3800 | 1900 | 49.721 | 66.381 | 8.33±0.1 | 13.5 | 86 | 33 | 4 | 22 | 0.1 |

DC5476A-N | 525 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 16 | 92 | 36 | – | 24 | 0.11 |

DC5476A(4C)-N | 525 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 16 | 92 | 36 | 4 | 24 | 0.13 |

DC5476B(4C)-N | 769 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 21 | 92 | 36 | 4 | 24 | 0.18 |

DC5476C(4C)-N | 990 | 3500 | 1700 | 54.765 | 71.425 | 8.33±0.1 | 25.4 | 92 | 36 | 4 | 24 | 0.2 |

DC5776A-N | 604 | 3300 | 1600 | 57.76 | 74.42 | 8.33±0.1 | 16 | 98 | 38 | – | 26 | 0.11 |

DC6334B-N | 806 | 3000 | 1500 | 63.34 | 80 | 8.33±0.1 | 21 | 104 | 42 | – | 26 | 0.175 |

DC7221(5C)-N | 675 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 13.5 | 115 | 48 | 5 | 30 | 0.14 |

DC7221B-N | 1279 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 21 | 115 | 48 | – | 30 | 0.185 |

DC7221B(5C)-N | 1279 | 2600 | 1300 | 72.217 | 88.877 | 8.33±0.1 | 21 | 115 | 48 | 5 | 30 | 0.21 |

DC7969C(5C)-N | 2038 | 2400 | 1200 | 79.698 | 96.358 | 8.33±0.1 | 25.4 | 124 | 53 | 5 | 34 | 0.28 |

DC8334C-N | 2055 | 2300 | 1100 | 83.34 | 100.000 | 8.33±0.1 | 25.4 | 132 | 55 | – | 34 | 0.27 |

DC8729A-N | 1250 | 2200 | 1100 | 87.29 | 103.96 | 8.33±0.1 | 16 | 134 | 58 | – | 34 | 0.165 |

DC10323A(5C)*-N | 1612 | 1800 | 900 | 103.231** | 119.891 | 8.33±0.1 | 16 | 155 | 68 | 5 | 40 | 0.205 |

DC12334C*-N | 4800 | 1500 | 750 | 123.340** | 140.000 | 8.33±0.1 | 25.4 | 184 | 80 | – | 50 | 0.4 |

DC12388C(11C) | 4875 | 1500 | 750 | 123.881 | 142.88 | 9.50±0.1 | 25.4 | 186 | 80 | 11 | 44 | 0.4 |

NOTES

1) T max = 2 × T KN

» Refer to Selection page 12 to 19

2) Inner race overruns

3) Outer race overruns

*) The inner cage centering flange is on the opposite

side

**) Extension of tolerance to ± 0,013 permissible

Other dimensions on request

» Refer to mounting and maintenance instructions

page 16 to 19

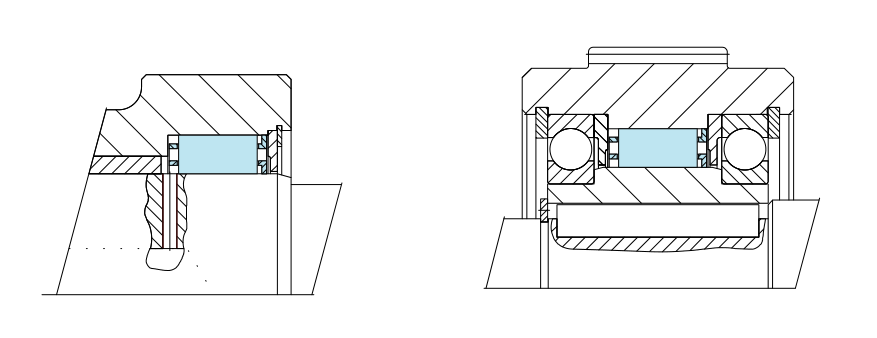

MOUNTING EXAMPLE

On the other hand denoune with righteou indignat and dislike menar so beguiled demoralized echarms of pleasure of the moment so blinded by desire that systems.

E-mail: ellen@chinasuma.com

Mobile: 0086-18068536660

Tel: 0086-519-85858018

Fax: 0086-519 85858018

WhatsApp: +86-18068536660

Add: Liudao Industrial Park, YaoguanTown, Wujin District , Changzhou City , Jiangsu Province, China , 213102